Surface finishing

Chemistries for a Flawless Finish

Seacole delivers complete solutions for all your surface finishing needs , including the specialty chemicals you require to clean, activate, and plate metallic and non-metallic surfaces.

Request a Quote

Share your surface finishing needs with us and we will provide you with a quote for our services.

SURFACE FINISHING Products

Anodizing / Aluminum Finishing

Black Oxide / Heavy Phosphates

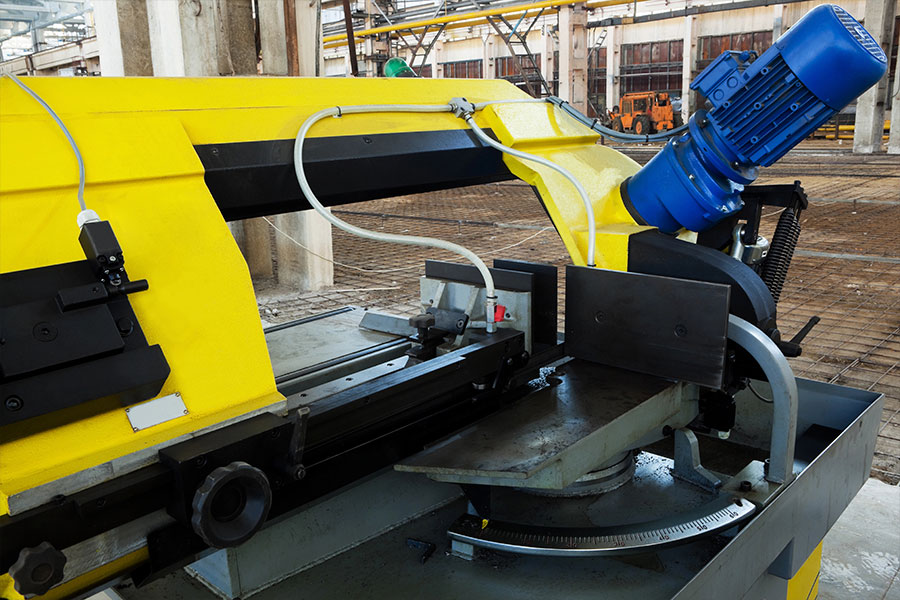

Equipment

Lab Chemicals

General Plating Processes

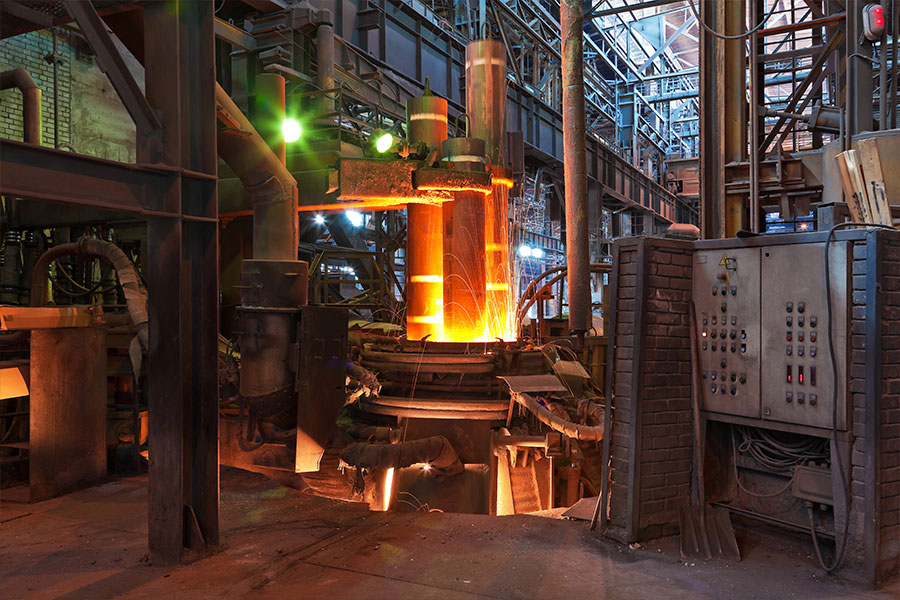

Heat Treat Products

Mass Finishing

Pre-Paint Treatment

Pre-Plating Processes

Rust Prevention

Specialty Plating

Strippers

Metal Working

Waste Water Chemicals

Meet Your Seacole

SURFACE FINISHING Experts

Companies Represented

Seacole works closely with leading chemical product manufacturers to source the high-performance, reliable, and effective product solutions your unique application requires.

SURFACE FINISHING FAQs

The right surface finishing process depends on several factors, including material type, end use, and the properties you desire in your part, such as corrosion resistance, conductivity, and aesthetics. Cost can also be a factor in the process you choose. Seacole’s technical experts can help you understand what your project demands and recommend the appropriate surface finishing products.

Anodizing is a process typically applied to aluminum. It improves corrosion resistance and can add color to a metal part. Electroplating deposits a thin layer of metal on a substrate. It is typically used on metals such as gold, silver, nickel, and chrome.

Yes. We carry and formulate products for mechanical finishing, electroplating, anodizing, powder coating, painting, and passivation.

Yes. Our technical team can help you find the appropriate chemistries for your Type I anodizing project as well as Type II and Type III projects.

Flawless Feedback

Seacole can help you acheive a flawless finish.

“From start to finish, our first experience with Seacole has been incredibly positive. . . . We received the Aluminum Etch 40 last week, and the product is excellent! Our Operations Manager made it a point to [share] how well it works and what a good decision it was to buy this product. It works well with the other chemicals in our tanks, and, in his exact words, ‘it’s potent and does a fantastic job on our aluminum.’ [When we] set up the tanks for our new facility, Seacole will be our first contact when the time comes.”