Surface finishing

Chemistries for a Flawless Finish

Seacole delivers complete solutions for all your surface finishing needs , including the specialty chemicals you require to clean, activate, and plate metallic and non-metallic surfaces.

Request a Quote

Share your surface finishing needs with us and we will provide you with a quote for our services.

SURFACE FINISHING Products

Our surface finishing products support a variety of processes, including anodized aluminum, electroless nickel plating, and other specialized plating processes. Our expert technical team will help you find the products that are appropriate for your process.

Anodizing / Aluminum Finishing

Surface finishing products for anodized aluminum and other aluminum finishing processes, from cleaners and etchants to dyes and seals.

Black Oxide / Heavy Phosphates

Chemistries to prepare, apply, and seal parts for black oxide plating and other heavy phosphate plating processes.

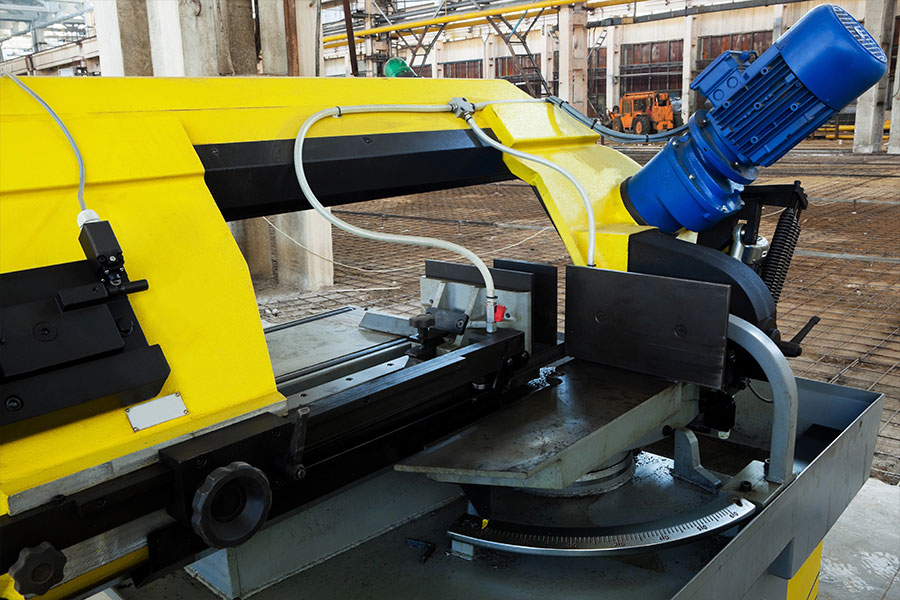

Equipment

Tanks, ventilation, hoists, flooring, rectifiers, heat exchangers, pumps, and filters, and installation of equipment for your surface finishing processes.

Lab Chemicals

Reagents for solution analysis from technical grade to high purity and semiconductor grade.

General Plating Processes

Prepare, plate, and post-treat all types of metallic and non-metallic substrates to enhance electrical properties, improve bonding, and extend corrosion protection.

Heat Treat Products

Surface finishing products for high-heat applications, standard neutral salt processes, and nitrating salts. Chemistries include quench salts, cleaners, and rust-preventative oils.

Mass Finishing

Chemistries for all stages of the surface finishing process, including deburring, burnishing, descaling, forming, and rust inhibition.

Pre-Paint Treatment

Cleaners, coatings, seals, and equipment for pre-paint treatment, including spray-wand and muti-stage wash line applications

Pre-Plating Processes

Acids, acid salts, and descalers to activate all types of substrates and accommodate any plating method, including soak, electro, spray, high- and low-temp, and multi-metal.

Rust Prevention

Water displacing oils for short- and long-term protection against corrosion, including aqueous-based corrosion inhibitors for all substrates.

Specialty Plating

Pretreatment and plating technologies that support the functional and decorative applications of metals onto plastic substrates.

Strippers

Surface finishing products for the removal of metallic coatings and non-metallic coatings, including powder and liquid formulations for low- and high-temperature applications.

Metal Working

Acid and alkaline metal etching compounds that minimize the formation of rust and etching and safely remove rust, oxides, mill, and heat scale.

Waste Water Chemicals

Chemistries for every stage of the wastewater treatment process, including acids, coagulants, deodorants, polymers, and precipitants.

Meet Your Seacole

SURFACE FINISHING Experts

Reach out with any process or product challenges — we’d be happy to help!

SURFACE FINISHING FAQs

The right surface finishing process depends on several factors, including material type, end use, and the properties you desire in your part, such as corrosion resistance, conductivity, and aesthetics. Cost can also be a factor in the process you choose. Seacole’s technical experts can help you understand what your project demands and recommend the appropriate surface finishing products.

Anodizing is a process typically applied to aluminum. It improves corrosion resistance and can add color to a metal part. Electroplating deposits a thin layer of metal on a substrate. It is typically used on metals such as gold, silver, nickel, and chrome.

Yes. We carry and formulate products for mechanical finishing, electroplating, anodizing, powder coating, painting, and passivation.

Yes. Our technical team can help you find the appropriate chemistries for your Type I anodizing project as well as Type II and Type III projects.